AGRICULTURAL DIAPHRAGM PUMPS

Diaphragm pumps are mainly used in agriculture for spraying and weed control and for the treatment of orchards, vineyards and olive groves.

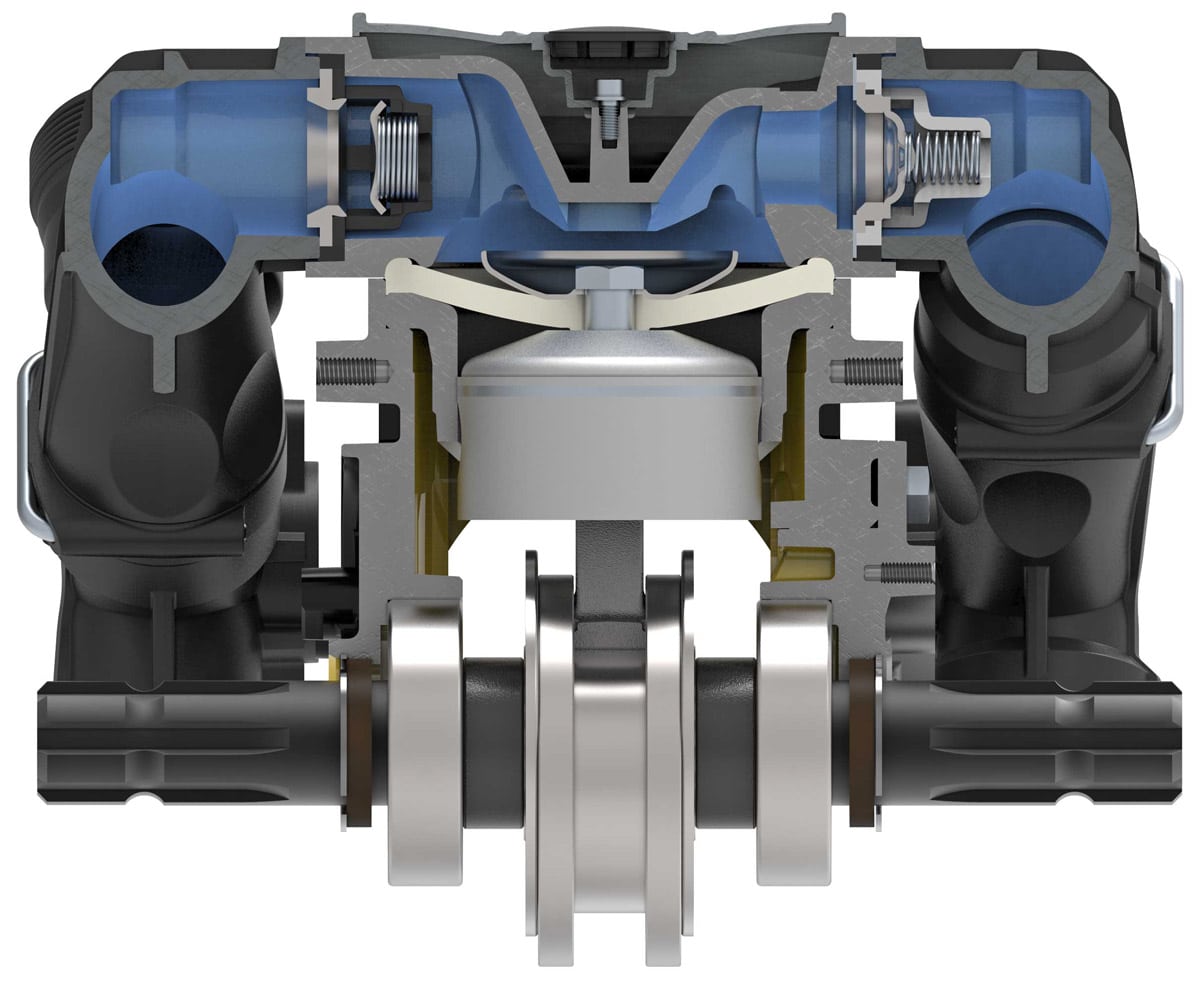

Diaphragm pumps belong to the category of positive displacement volumetric pumps, which exploit the alternating variations of the volume of a chamber (expansion and contraction) to generate imbalances in pressure and give rise to the pumping of the liquid.

In agriculture, these pumps are used for spraying and weed-killing treatments to protect crops from pests. Diaphragm pumps are divided into:

- Low pressure pumps: up to 20 bars

they are intended for application on boom sprayers for the treatment of open field crops: cereals, tomatoes and vegetables. - High pressure pumps: between 30 and 50 bars

they are used on atomizers for the treatment of vineyards, orchards and olive groves.

The main advantages of using diaphragm pumps in agriculture are: excellent priming and self-priming capacity, good dry running capacity and mechanical-chemical resistance and resistance to chemicals.

HIGHLIGHTS

BPS SERIES

The new range of Comet 3 to 6 diaphragm low-pressure pumpsThe new range of Comet 3 to 6 diaphragm low-pressure pumps

The BPS line boasts a series of major features unparalleled on the market: reduced overall dimensions, ease of maintenance, long life and resistance to heavy duty operating conditions, while always providing high performance in terms of flow rate, priming capacity, power absorption and silent running.

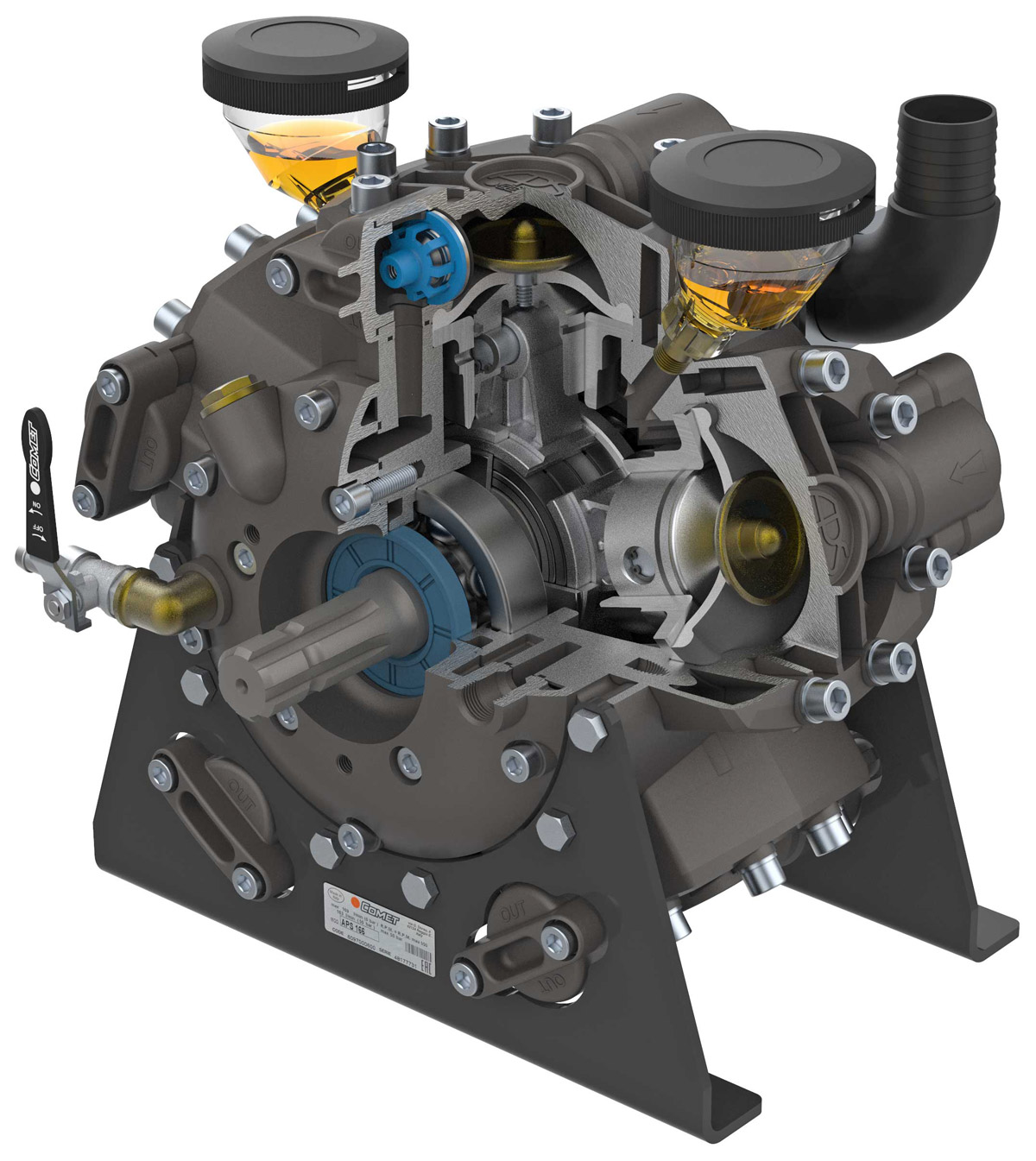

APS SERIES

The global benchmark for spraying pumpsThe global benchmark for spraying pumps

The APS series is the international byword for highpressure spraying pumps. This exceptional reputation has been achieved by Comet through decades of technological improvements, in order to meet the most demanding needs of customers looking for a pump that is simple to use, reliable and heavy-dut.

IDS SERIES

The indestructible Comet High-Pressure brass pumpsThe indestructible Comet High-Pressure brass pumps

The IDS series is Comet’s top-of-the-range, and it is world-known for its unmatched reputation in the field of brass pumps. IDS pumps have been engineered for heavy-duty applications in orchards, vineyard and olive crops and are capable to adapt to the harshest conditions.

YB SERIES

The plunger pumps for hyperintensive useSpraying Units

Control units and accessories

AGRICOLTURAL BLOG NEWS

Installation and operation of a diaphragm pump

In order to obtain correct operation and the best operating results, a number of important measures are essential, starting with the preparation of the safety devices (pressure unloader valves, safety valves, cardan shaft cones, etc.) together with the correct sizing of hoses and filters.

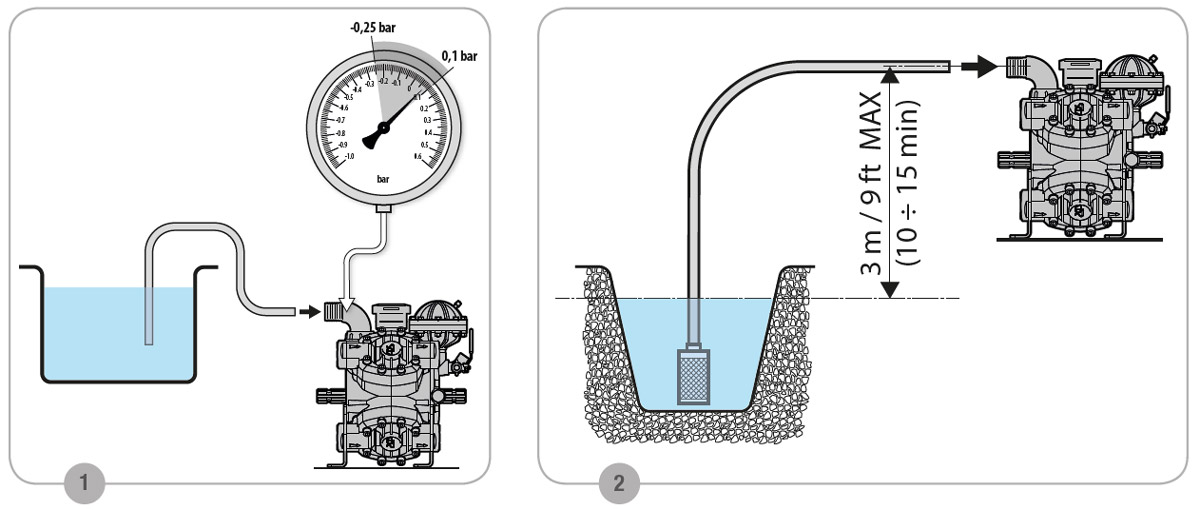

One of the most important recommendations is that the pump should never be fed from a positive pressure water source (e.g. water supply or other pump), since positive pressure can interfere with valve closure and result in early component wear.

The diaphragm pump must also be installed below the level of the feed tank so that the liquid can flow to the pump at natural atmospheric pressure and avoid cavitation.

In case of feeding from canals, reservoirs or tanks located below the pump, the feeding occurs by suction, i.e. at negative pressure (vacuum). In this case, make sure that the water level is no more than three meters below the pump’s suction fitting in order to avoid the aforementioned cavitation.

Read also: THE COMPONENTS OF A DIAPHRAGM PUMP

Low pressure pumps for boom systems

The modern sector of agricultural machinery for crop protection involves the use of machines with increasingly high performing boom sprayers and new intensive cultivation techniques require that all components, especially the diaphragm pumps, ensure high resistance to the harshest work conditions, thus maintaining high performance in terms of flow rate, priming capacity, power absorption and silence.

A perfect piston stroke/bore ratio is also required to minimize the stress on the diaphragms, thus ensuring low maintenance, maximum durability and excellent priming capacity.

For bigger agricultural machines, pumps are often combined in tandem, to increase the overall flow rate or allow the synchronous use of multiple applications (spraying / stirring / recirculation).

The characteristics of diaphragm pumps for bar systems are high flow rates (up to and over 600 l/min) and low pressures (between 10 and 20 bars). All parts in contact with the pumped liquid (heads and manifolds) are made of techno-polymers or protected by plasticizing treatment to increase resistance to chemical agents.

Read More: BPS Series

High pressure pumps for atomizers

In high pressure pumps the reduced space available on the atomizers makes it essential that the pumps feature a design as compact as possible.

They must also be hyper-resistant, that is, able to withstand high axial and radial loads (cardan shaft thrusts) and be able to transmit maximum power to the turbine. For this reason, the transmission components and pump supports must guarantee maximum strength and resistance to stress.

The use of extremely aggressive chemical products makes it necessary for the parts in contact with the liquid (heads and manifolds) to use anodized aluminum or brass, the latter being a material that is able to withstand abrasion and chemical corrosion better than any other.

Read also: HOW TO CHOOSE THE DIAPHRAGM PUMP BY COMET WHICH BETTER FITS TO YOUR ATOMIZER

Diaphragm pumps for crop treatment

The crop treatment sector is now oriented towards self-propelled machines or large hyper-performing trailed machines, which are able to cover large cultivated areas in the shortest possible time. The total area of farms is in fact constantly increasing and therefore requires bar systems of ever increasing size and efficiency.

Just like the machines, even the most important components such as the diaphragm pumps must guarantee excellent performance, in particular high flow rate (allowing the supply of longer and longer bars) and high priming capacity (for the rapid loading of large tanks from canals or reservoirs).

At the same time, the modern design of the self-propelled and trailed machines requires compact pumps with reduced overall dimensions, which can be easily placed in limited spaces.

Another fundamental feature of modern pumps dedicated to the treatment of crops is the ease of maintenance, to allow rapid intervention in case of an emergency without wasting precious time during the weed control season.

Diaphragm pumps for the treatment of vineyards and orchards

Vineyards, orchards, citrus and olive groves: for all these fields of application, the atomizers are the machines used for the protection treatments and the diaphragm pumps are their core.

The very heavy work which is characteristic of this kind of crop makes it necessary for the pumps to be made with particularly sturdy components (bearings, shafts, support brackets, etc..) capable of ensuring effective resistance to axial thrusts and a long life over time, adapting to the harsh conditions of dry, dusty and overheated environments in which they are intended to operate (e.g. tropical or subtropical climates).

Oversized diaphragms combined with low stroke pistons drastically reduce the fatigue of the moving parts, thereby increasing the service life of diaphragms, valves and consumables in general.

For this type of use pumps made of brass are often used since they are more resistant to aggressive chemicals.

Maintenance and troubleshooting of the diaphragm pumps

Regular maintenance is the best investment to increase the service life of both pumps and sprayers.

For this reason every 300 hours of operation or at the end of the agricultural season (the one that occurs first) it is advisable to:

- replace the diaphragms,

- check the status of the valves

- change the oil.

Before maintenance, the inside of the pump must also be rinsed thoroughly with clean water.

The main problems that may arise during the operation of a diaphragm pump can often be solved by simple measures (e.g. checking the cleanliness of the filters or changing the worn nozzles) or by correctly adjusting the operating parameters of the pump itself.

In case a diaphragm breaks, it is very important to identify the cause and intervene to prevent the recurrence of this episode.

For more serious problems, it is always advisable to contact an authorized service centre.

Comet diaphragm pumps

Comet S.p.A. is a world leader in the field of diaphragm pumps for spraying and weed control. A position built over 60 years of experience and consolidated by an incessant thrust for the development of new products, with the aim of satisfying customers’ needs and requirements.

The Company holds the ownership of numerous patents for important technological innovations, which guarantee a fundamental competitive advantage over all its competitors.

The Agricultural Division’s production covers the entire range of low, medium and high pressure diaphragm pumps. Quality is guaranteed by the careful selection of components and the meticulous series of tests to which all prototypes are subjected before reaching mass production.

The key to Comet’s success is to look to the future without leaving the past behind, thus “dressing” the quality and meticulous craftsmanship that distinguish the Italian manufacturing tradition with the modernity of an international approach that lays its foundations on the quality of products and on the constant improvement of the services offered.